V Necklace

/ Practical non-linear slicing

Taking full control

Advances in software such as Rhino and Grasshopper in the mid-2010s allowed designers to experiment with new ways of generating 3D printer toolpaths that had previously only been generated by software such as Cura or Slic3r. The ability to completely control the position, flow ratio and speed in three-dimensional space, as well as a coherent printing sequence, allows the production of high-strength parts that take full advantage of the full range of material capabilities of FDM and LDM.

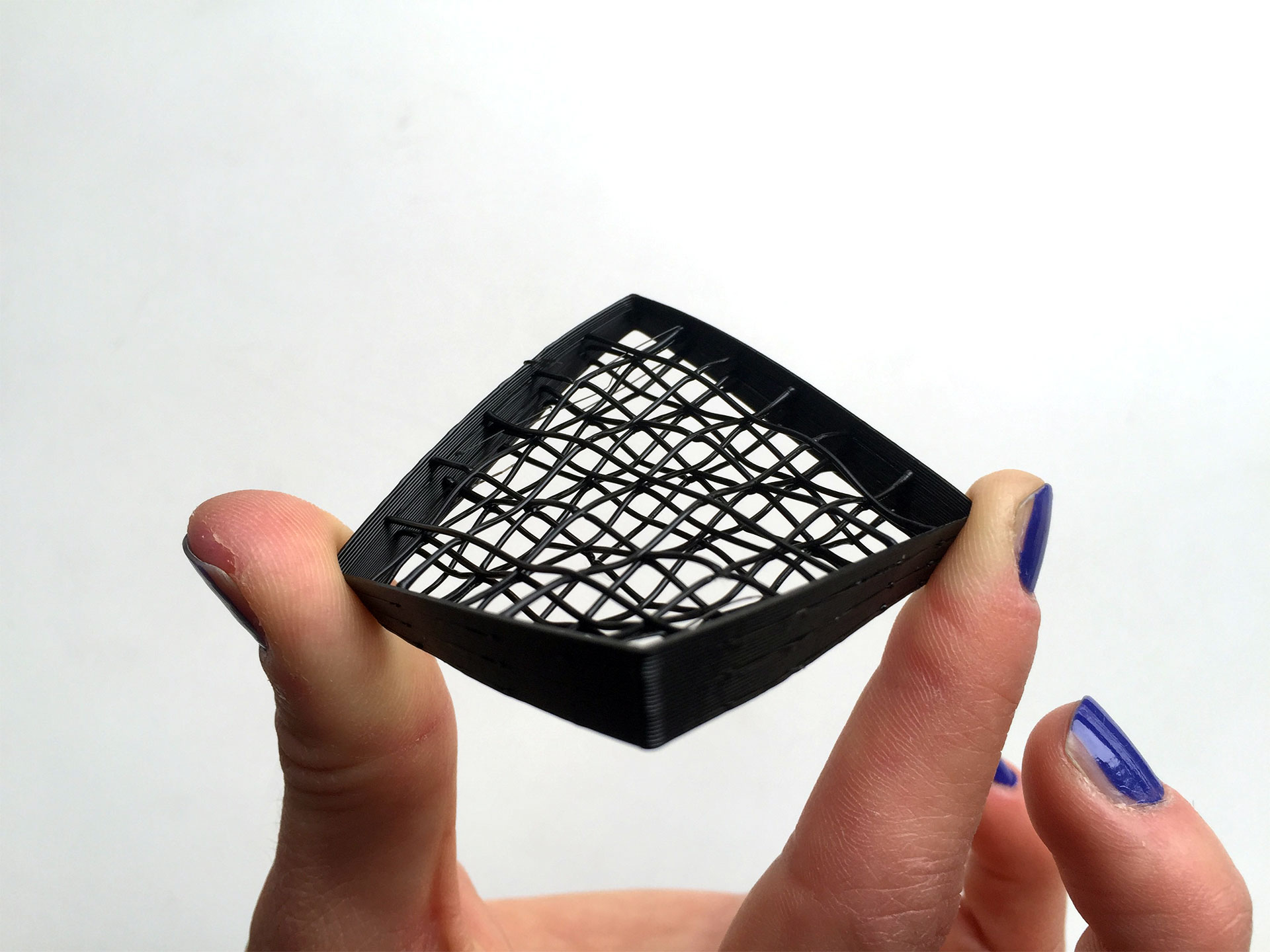

Modifications to the geometry composing the object, such as infills, perimeters, and closing surfaces, significantly affect the mechanical behavior, and the combination of different geometries and materials opens up many new possibilities.

I have designed a new three-dimensional adaptive infill that reduces the weight of the object while maintaining the span between the supports for the top and bottom surfaces. The object has also shown an elastic response that can be tuned by controlling the geometric parameters.

Published on:

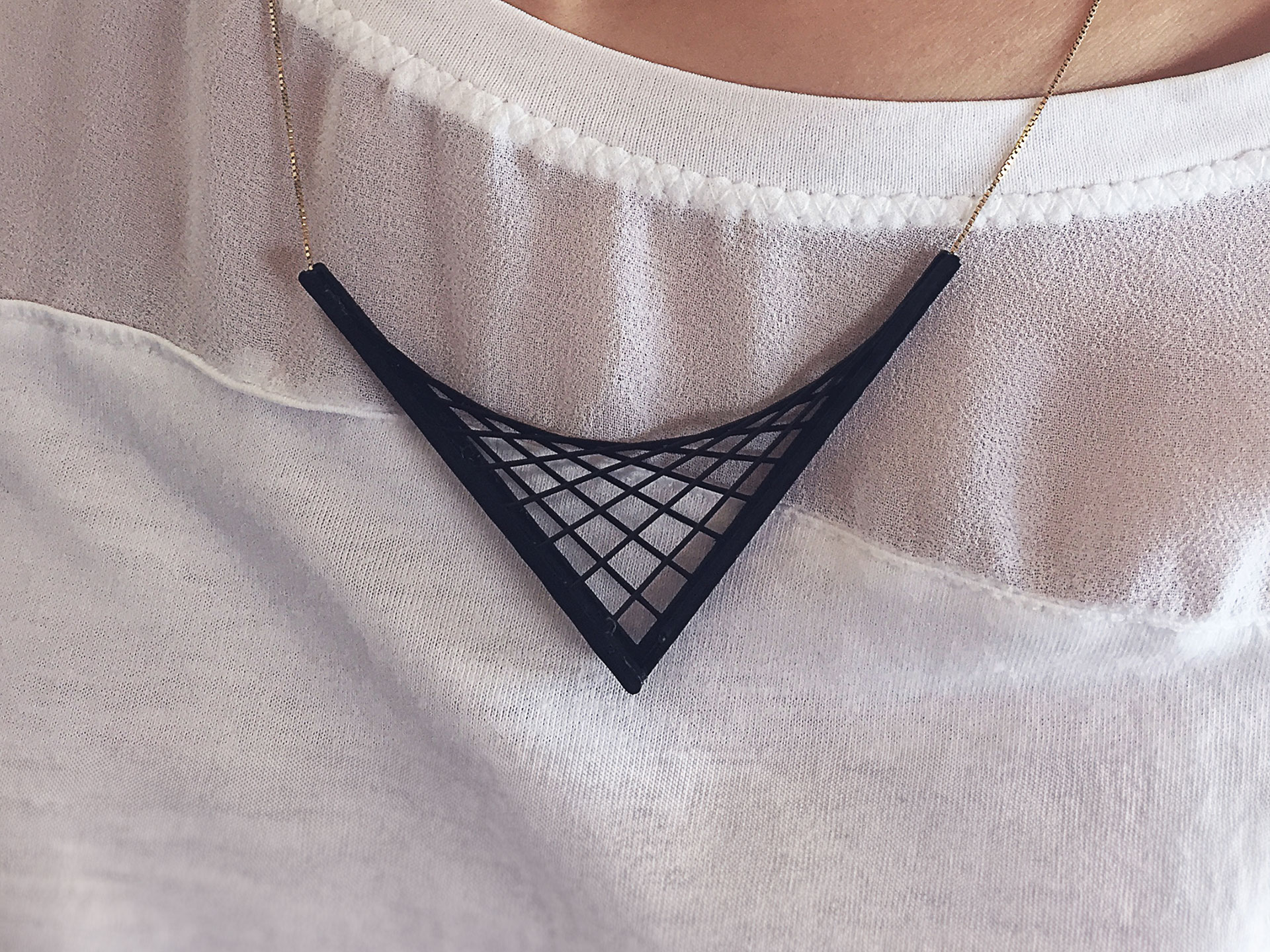

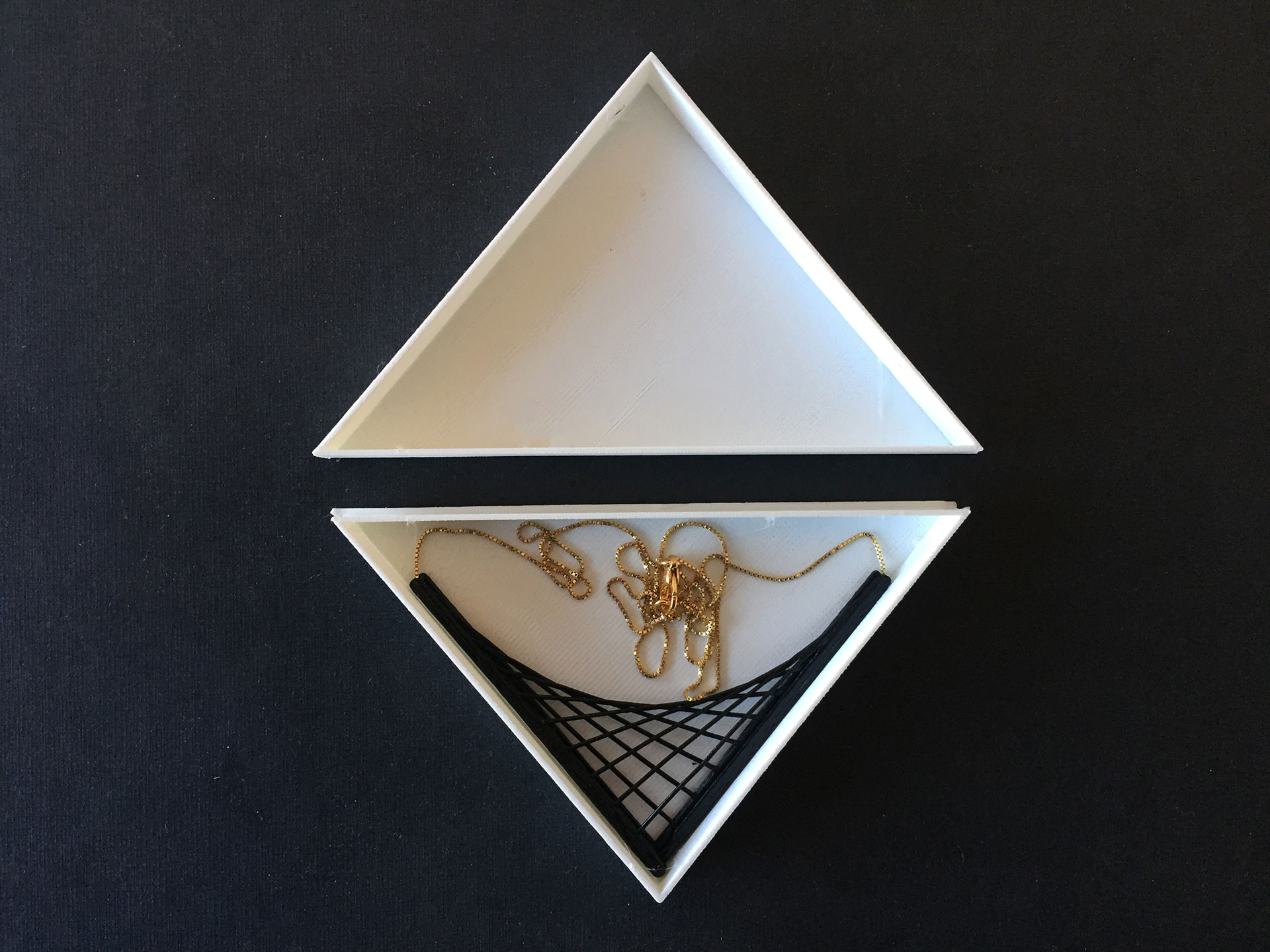

A unique necklace

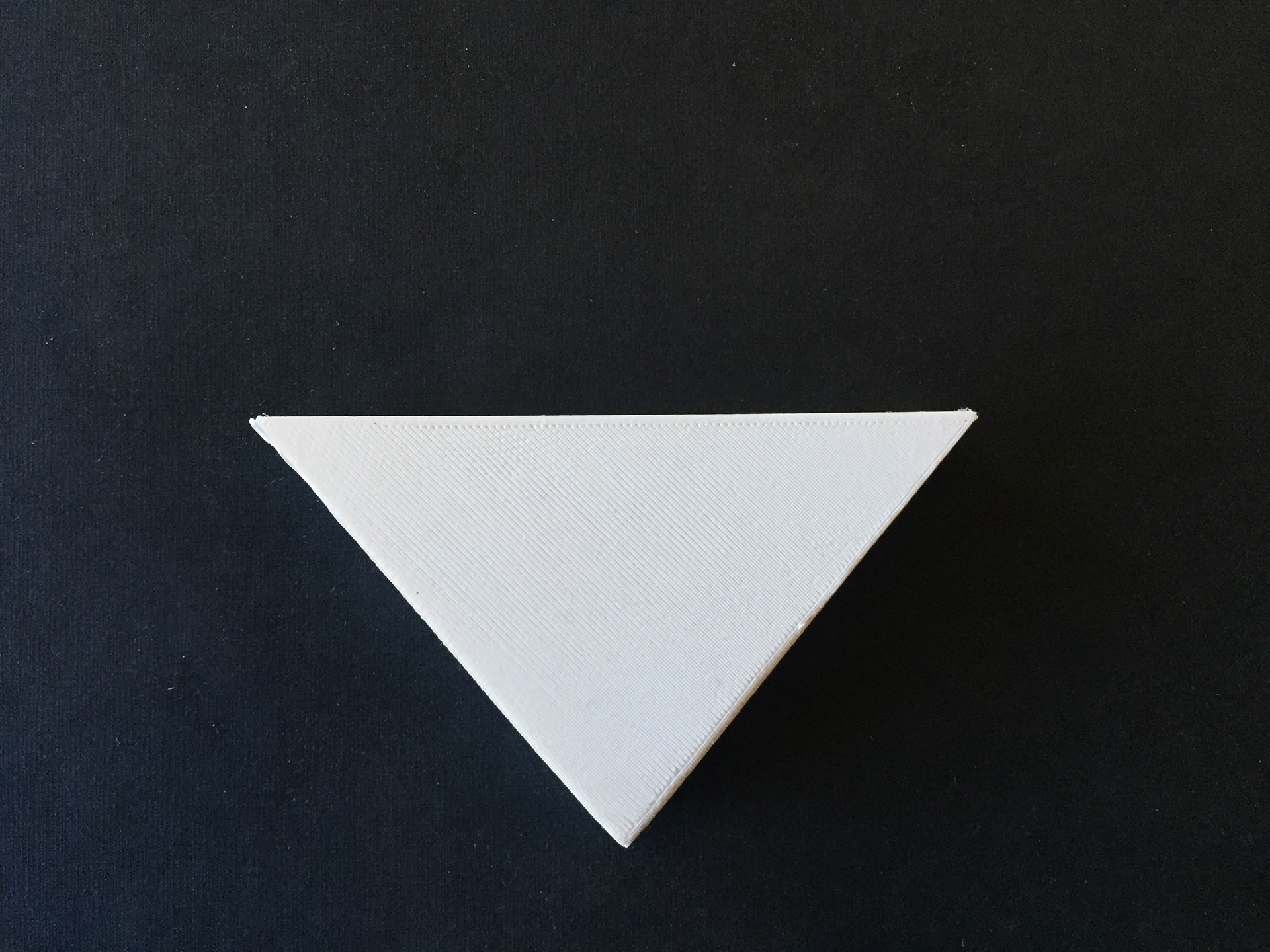

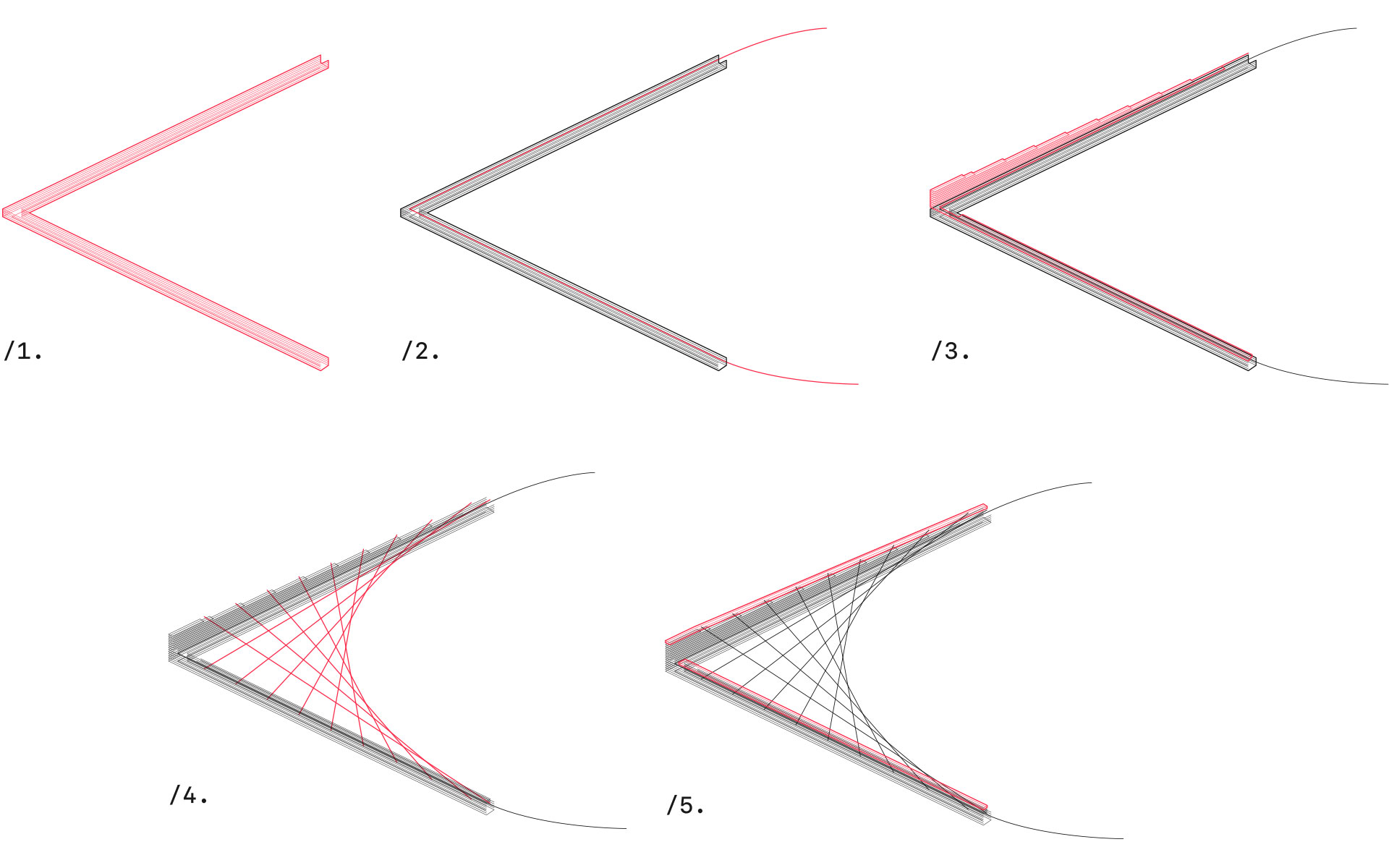

To demonstrate the application in a practical environment, I designed a necklace based on the ruled surface principle. This principle allows curved geometries to be described using straight lines. In this case, a series of lines are printed without supports, in three-dimensional space, connecting two sides of a square and writing a V, hence the name of the project.

In order to have a unique element without the need to connect the chain, the necklace is printed in sequence. First, the base is realized, leaving space for the chain that will be subsequently positioned by a human. Molten plastic is poured by the 3D printer onto the chain to solidify the connection, and then the rest of the ruled geometry is completed on top.