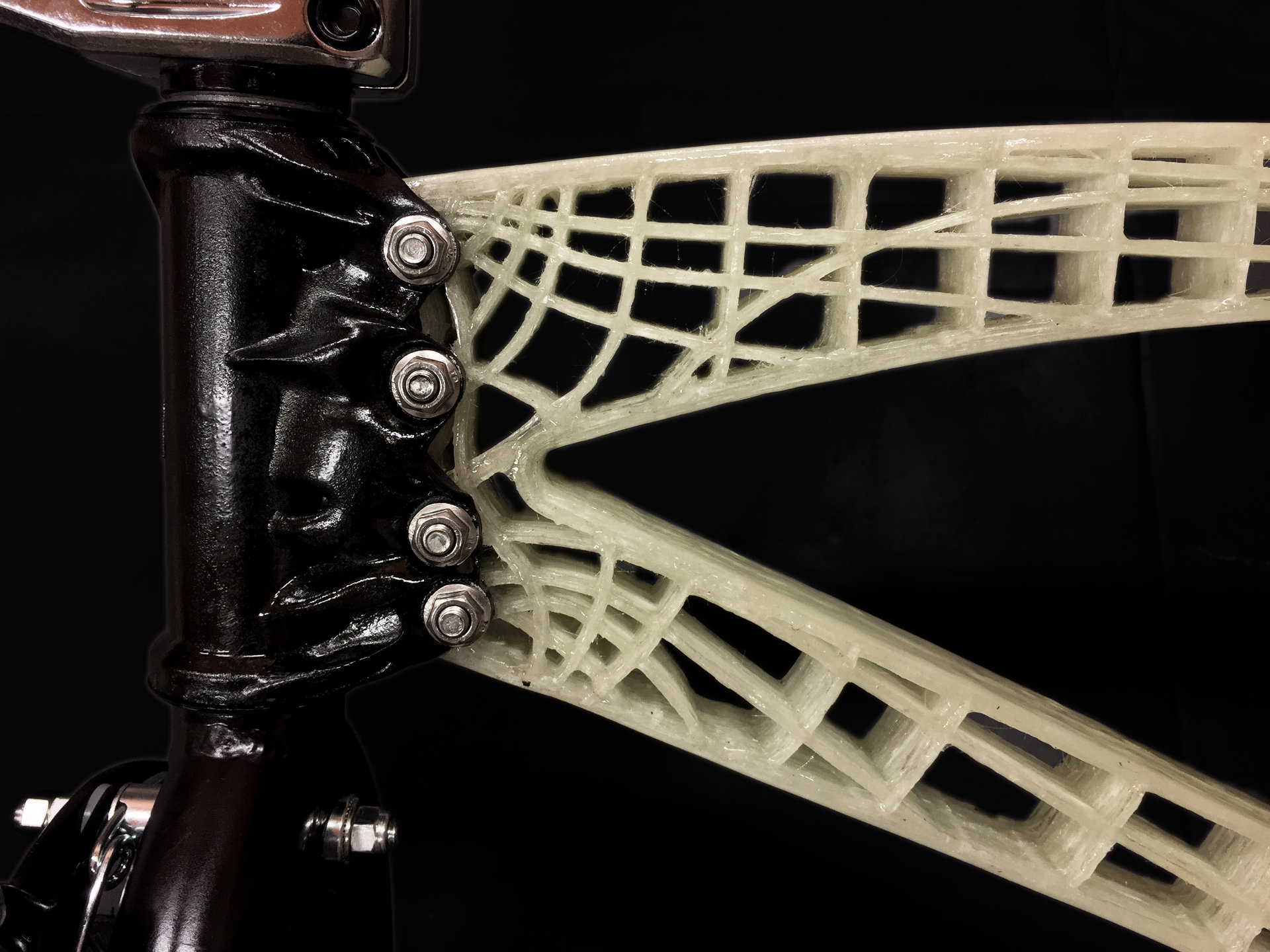

Wire Frame

/ Topological optimization of continuous fibers

Made in collaboration with

Industry's first

The redesigned BMX Frame marked the beginning of our collaboration with Autodesk, a multinational software corporation. This design was created to highlight the capabilities of Autodesk's Netfabb software, particularly in the areas of additive manufacturing and topological optimization.

The BMX was displayed at Formnext 2017 in Frankfurt, Europe's largest additive manufacturing exhibition.

Optimization algorithms

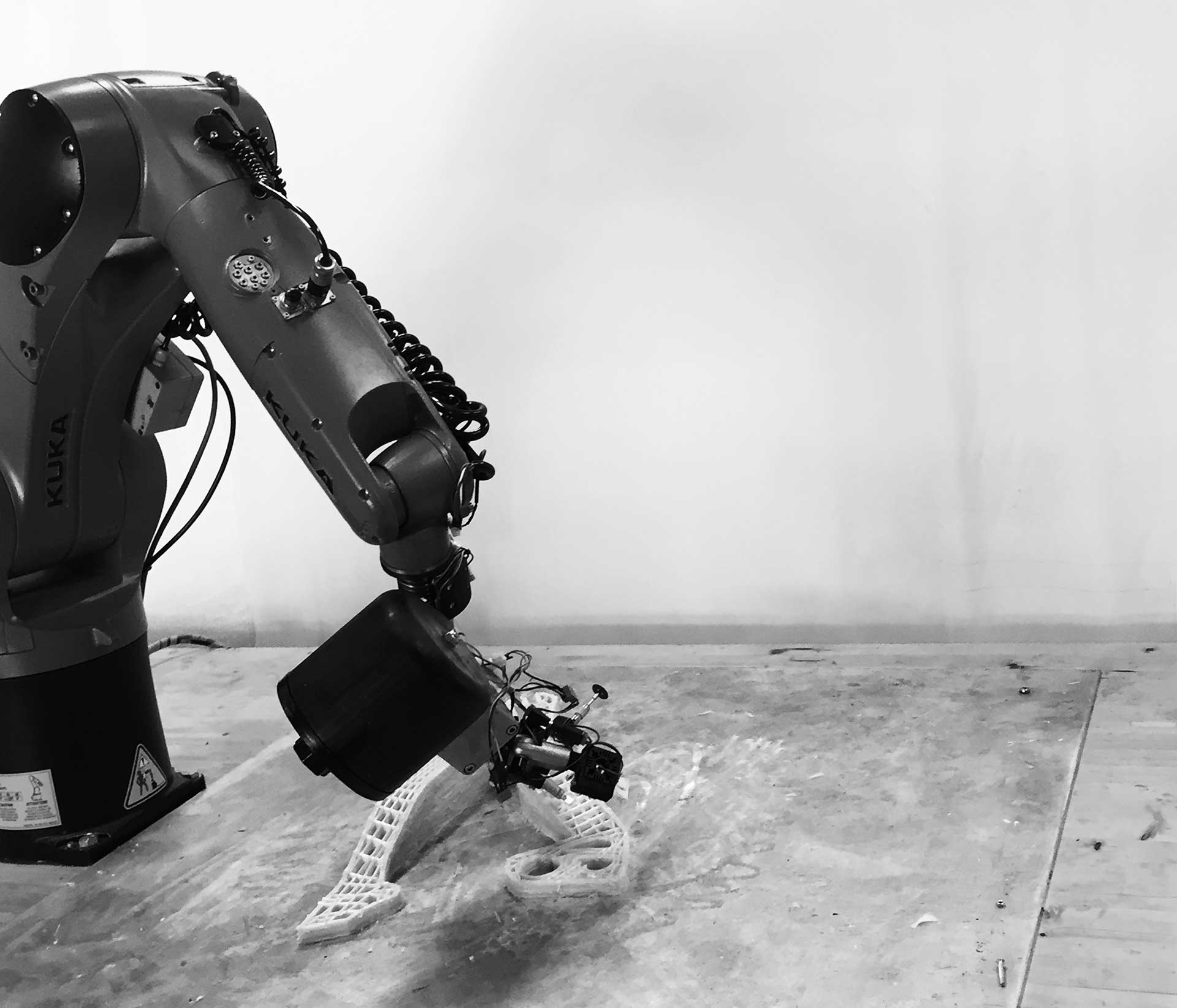

Two algorithms were developed for this project and were subsequently implemented in moi's tool pathing software. Both algorithms are voxel-based and are built on top of Millipede, a renowned Grasshopper plugin for structural analysis and topological optimization. The first algorithm was utilized to design the overall shape and to remove superfluous materials, whereas the second determined the directions of maximum stress, which then guided the robot's path.

Lastly, Autodesk Netfabb, combined with the Additive plugin—now a part of the Fusion360 suite—was employed to import these paths and generate a robotic toolpath.

Printing fine tuning

For this project, which utilizes continuous fiber, specific 3D printing algorithms have been developed. These algorithms are designed to join fibers in a way that maximizes a single path, thus making the printing process more efficient. As a result, the time required for the cutting phase has been substantially reduced.

An initial, basic fiber cutting mechanism was introduced for this project. This laid the foundation for subsequent advancements.