Atropos

/ Redefining composites manufacturing

Published on:

Learning from nature

Atropos, in Greek mythology one of the three Moirai, is the name of the research project born at +LAB, Politecnico di Milano, where CFM technology - Continuous Fiber Manufacturing - was developed. This became the foundation of Moi Composites.

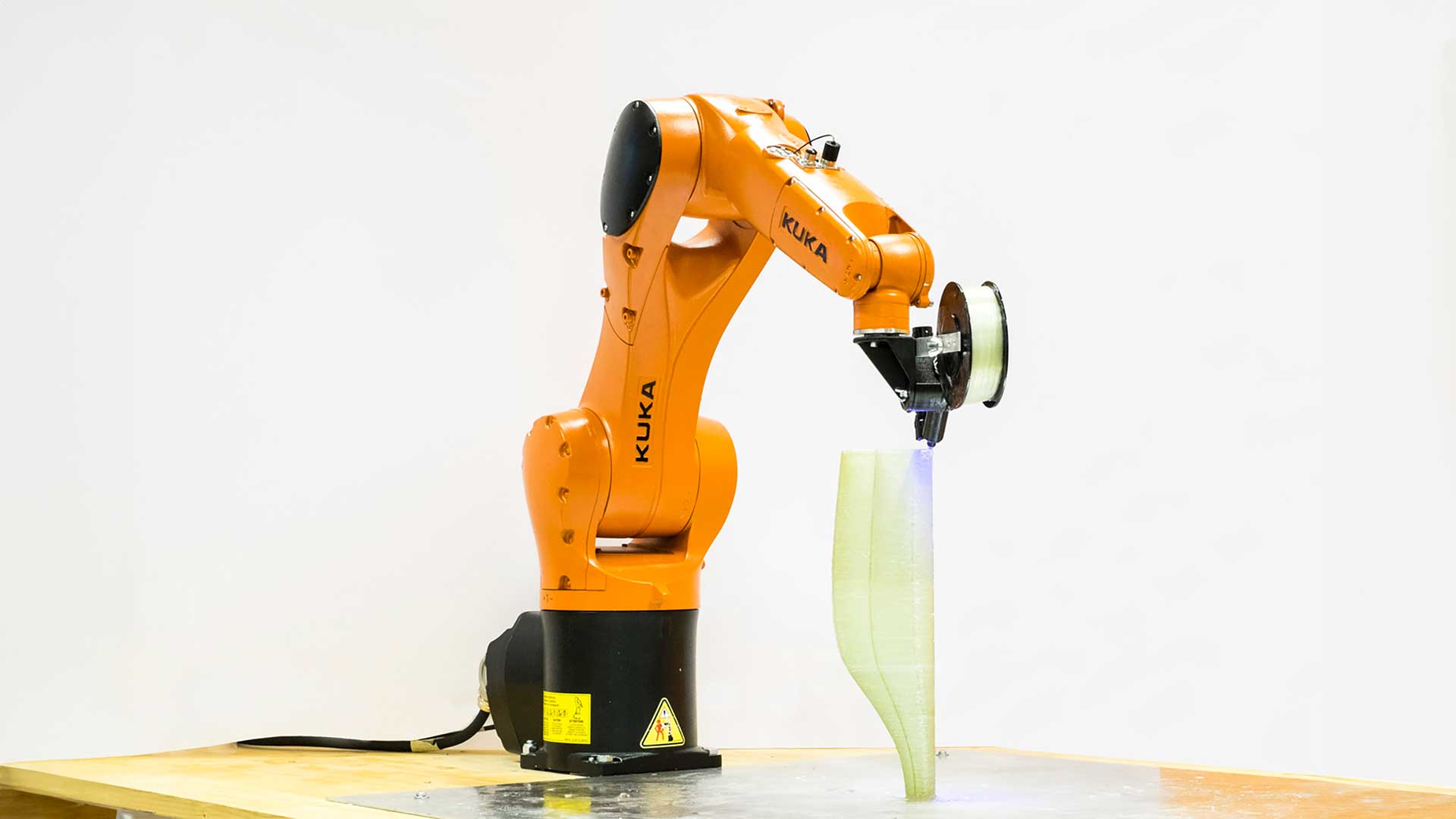

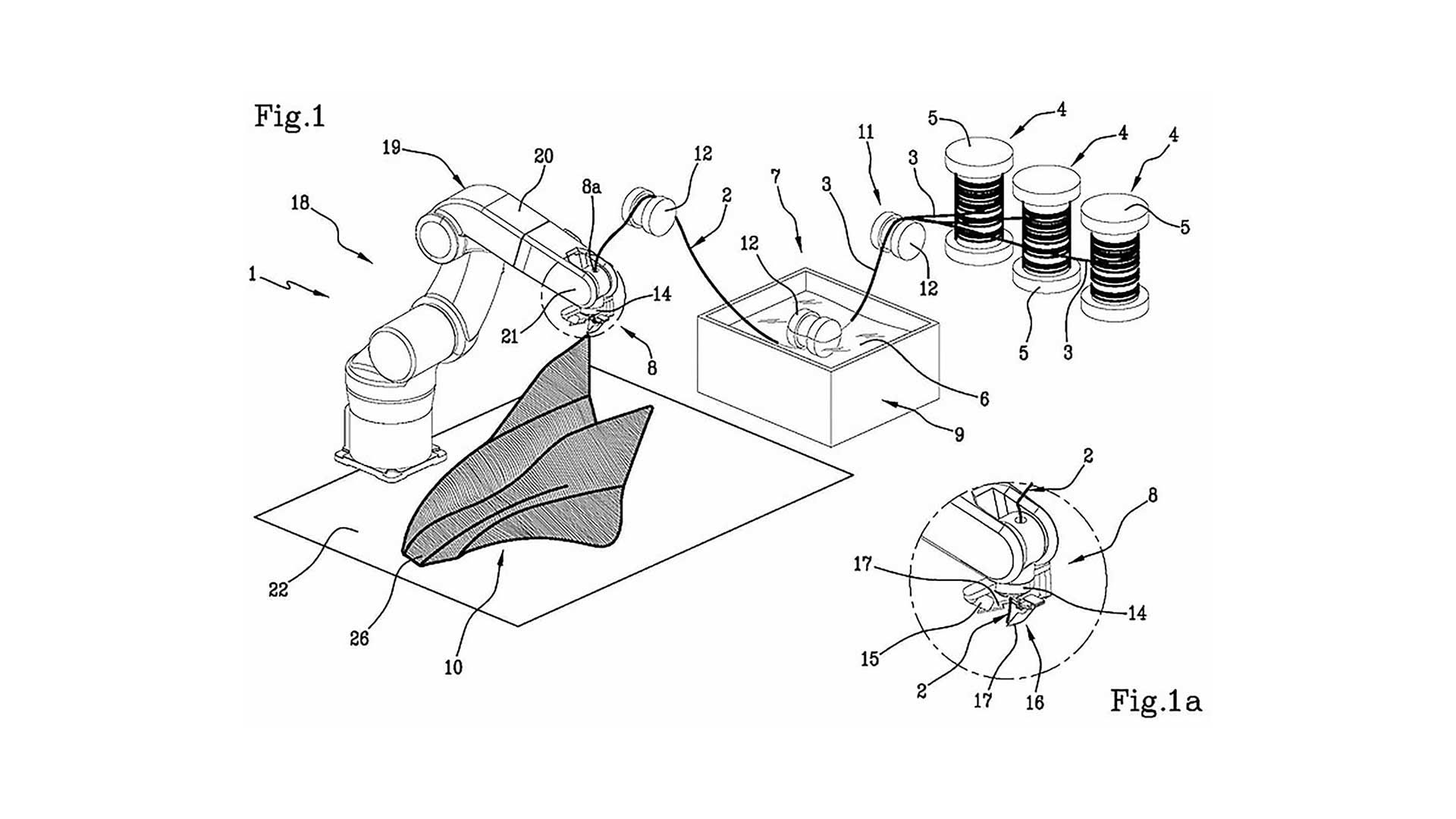

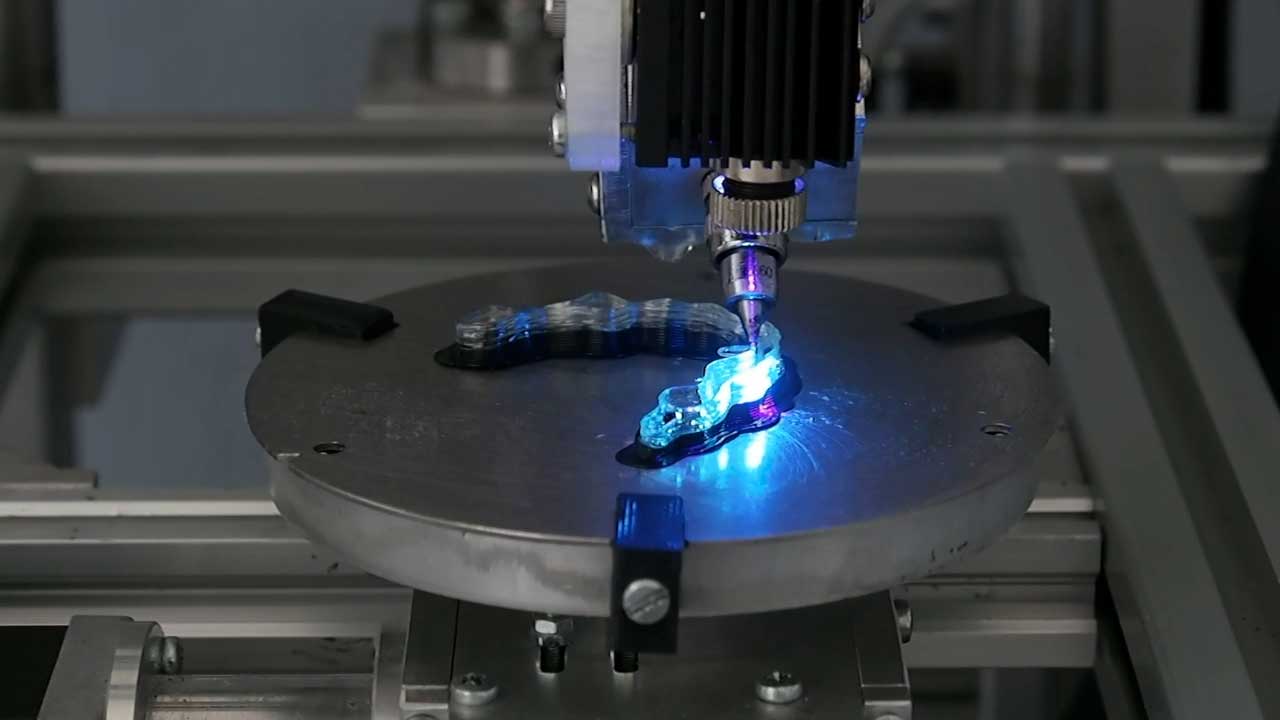

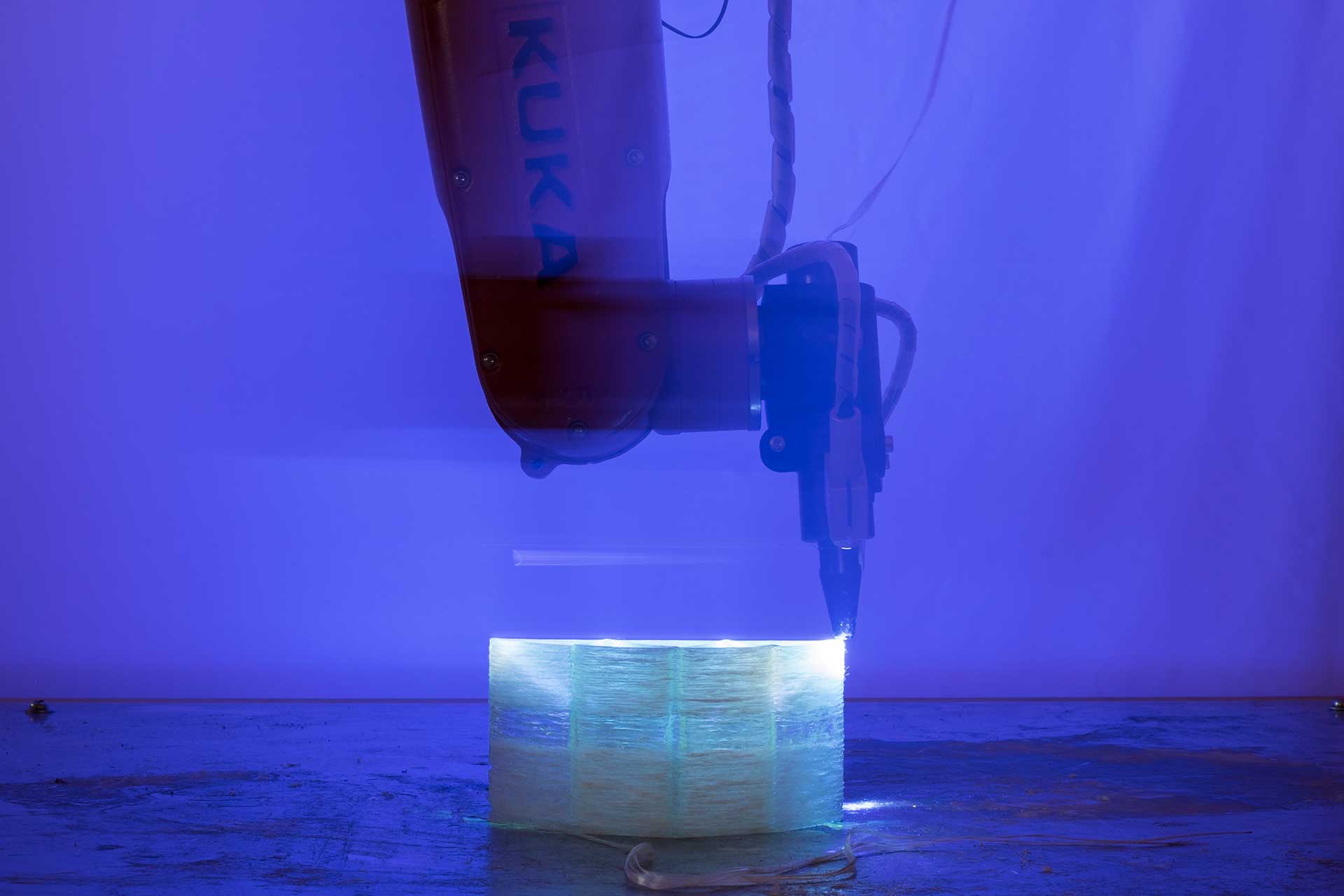

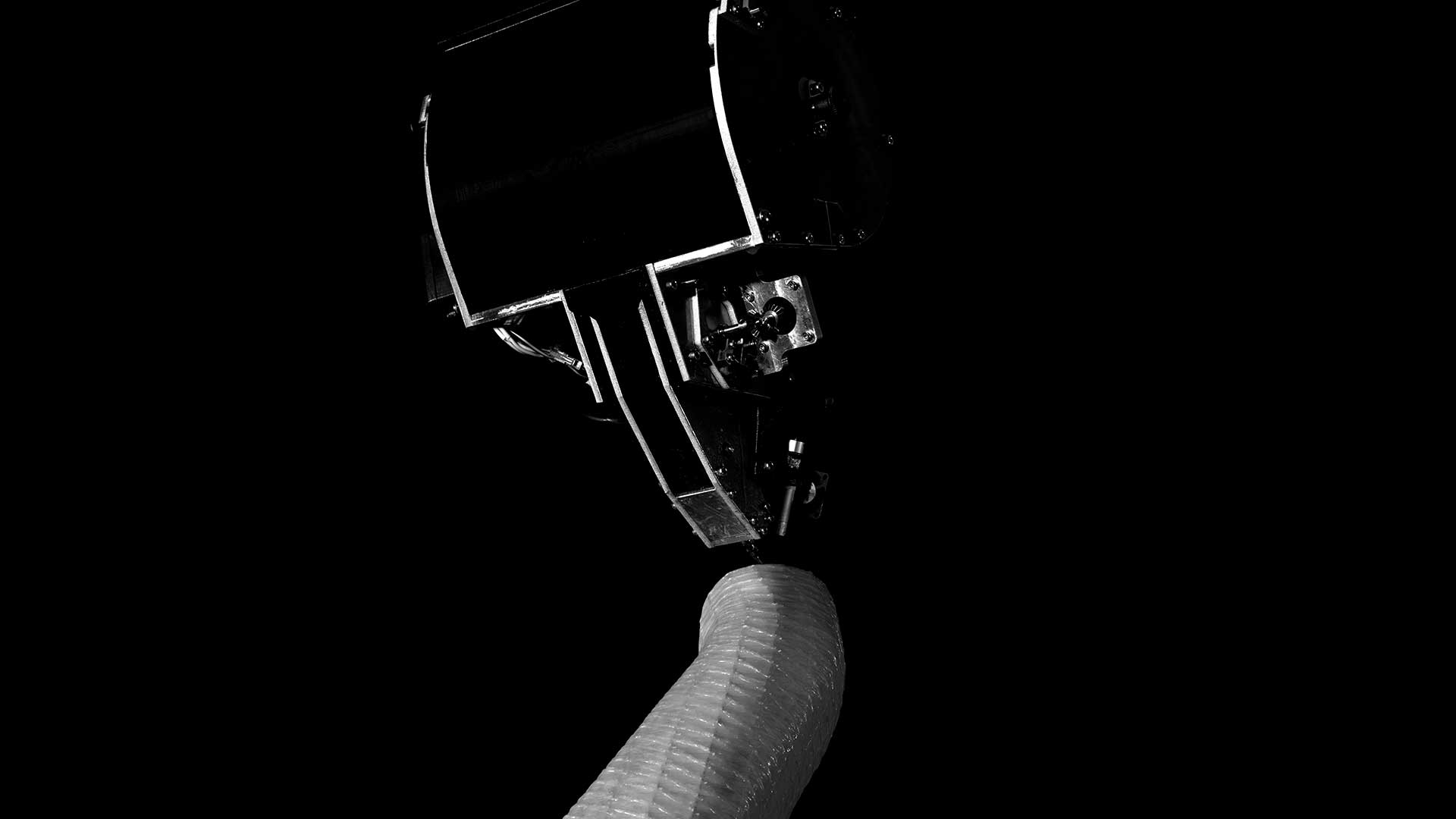

Inspired by nature and silkworms, and controlled by the artificial intelligence of special algorithms, Atropos fluently moves in space depositing a continuous fiber of thermosetting composite material, instantly cured as it comes out of his head.

A new era of manufacturing has born, combining the quality of custom-made product with the performance of technological artisanship.

A material library

To accommodate a variety of applications, from biomedical to aerospace, a material library was developed. This is based on a modular system where is possible to mix and match different resins with various fibers, achieving a composite material with the desired performance.

A software suite

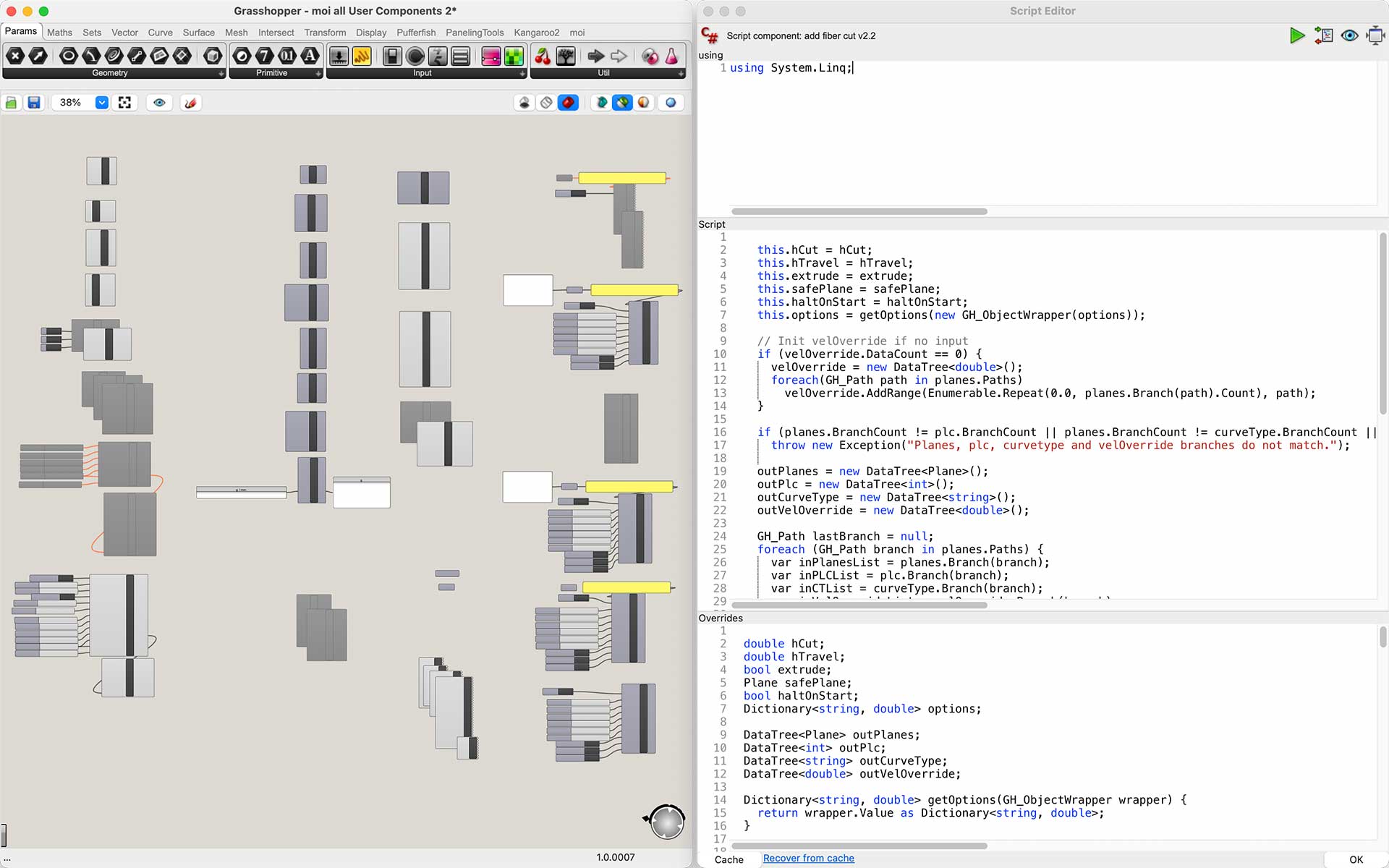

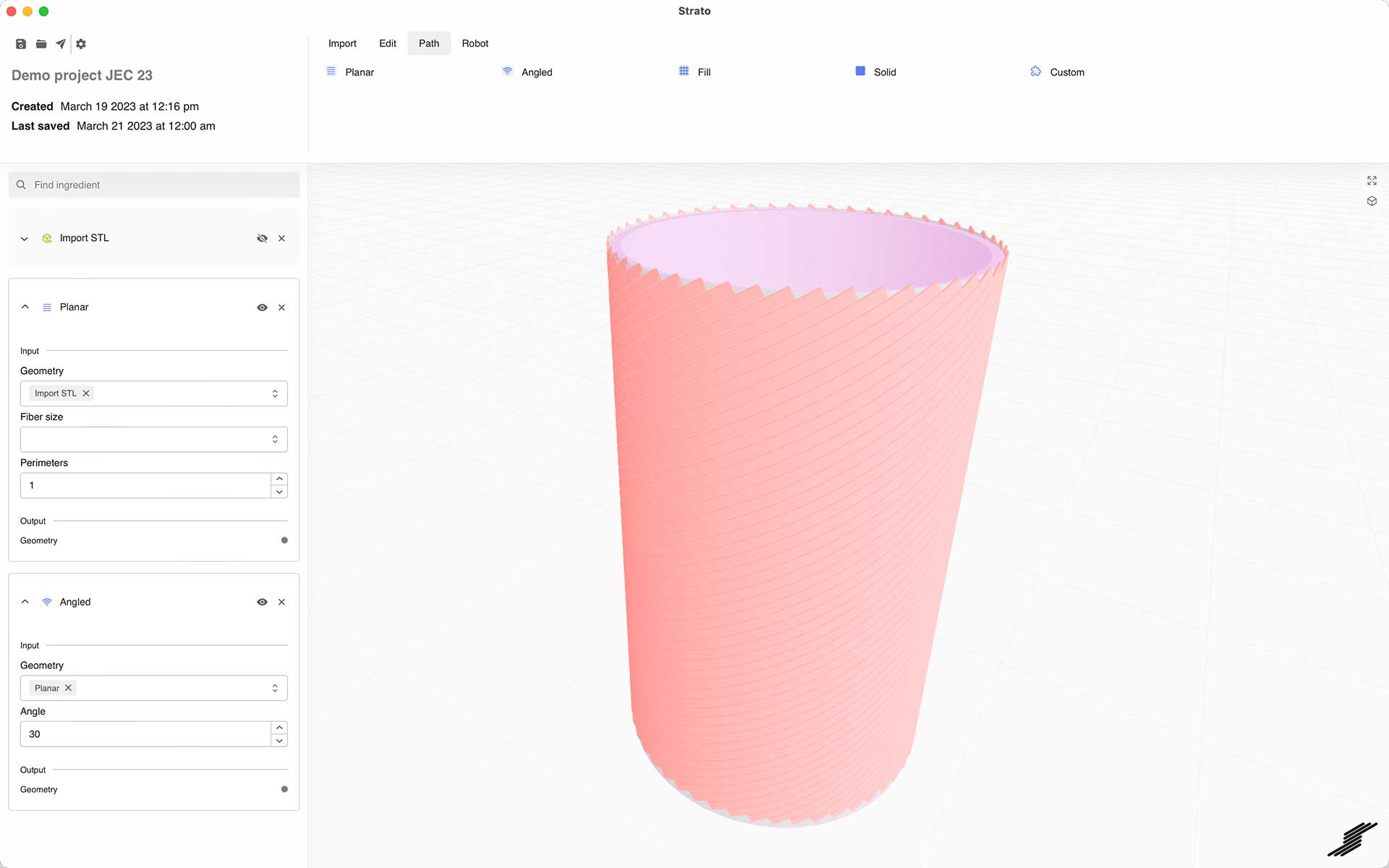

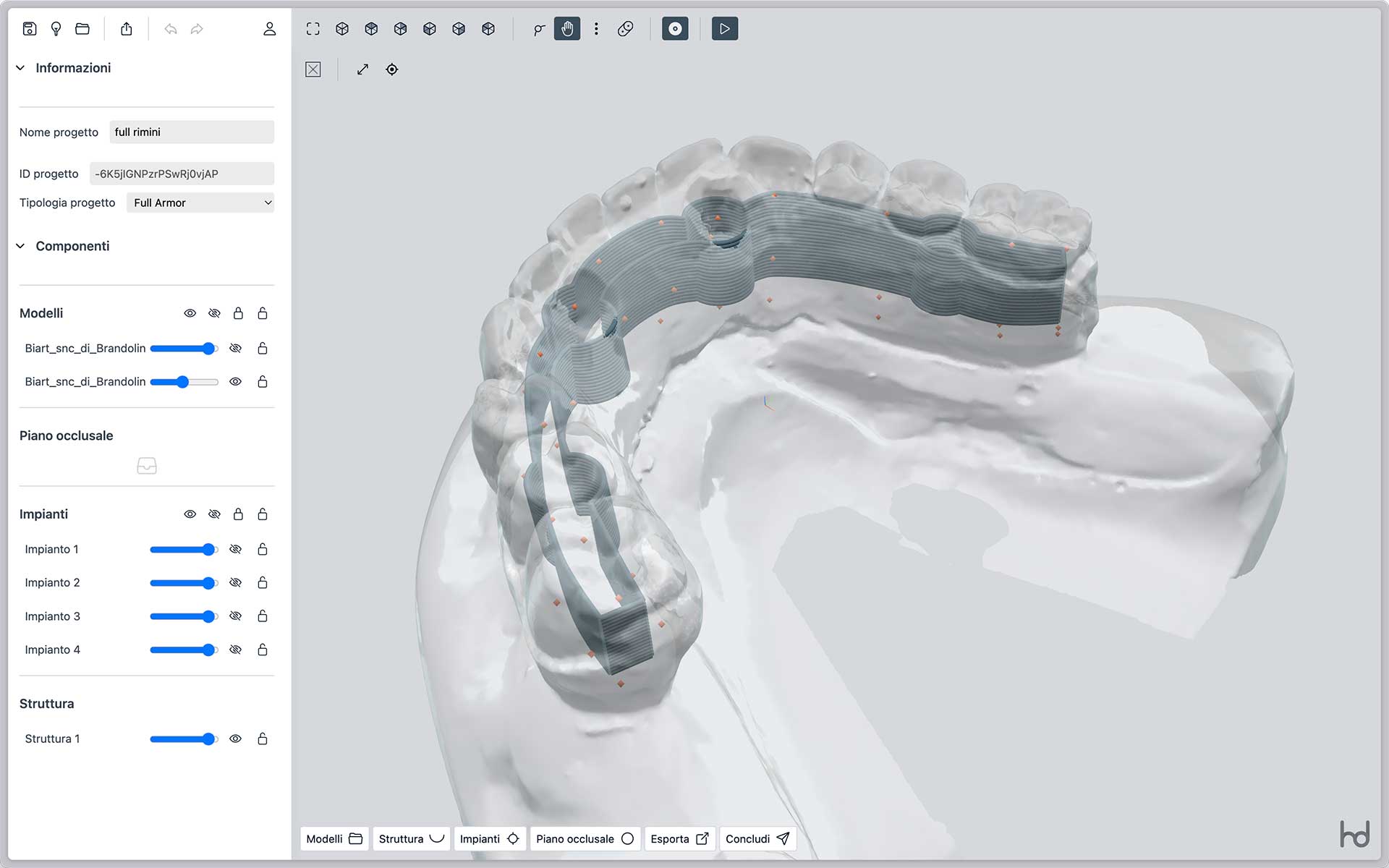

To quickly iterate and improve the code for path planning and the robotic simulation of CFM technology, a set of more than 30 Grasshopper components was developed, combining RhinoCommon API calls with custom algorithms. After testing, these components were included into the suite of CAD and CAM software. Strato powers the slicing and robotic control of all the systems, while Hi-Design is a web-based CAD software for dental prostheses.

An integrated platform

Sistema, Italian for System, is the robotic platform that enables the creation of composite parts through digital technologies and additive manufacturing. It's a flexible system that can be scaled down to bite-sized dimensions or up to print boats. It can be equipped with various heads, capable of depositing a range of materials, from short fiber-reinforced resins to continuous fibers, also including finishing tools.